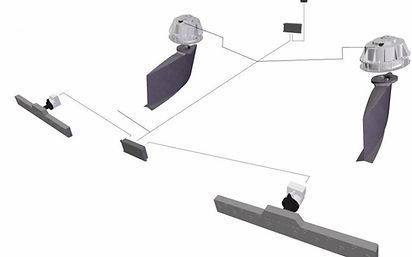

SERVICES - BOW THRUSTER

Disassembly and reassembly

Ordinary and extraordinary maintenance, replacement of defective elements, gaskets, greasing, etc.

Tests, checks and operational verifications

Overhaul, arrangement and possible replacement of hydraulic motors with PTO-type towed pump or independent with electric motor

Transmission control between hydraulic motor and propeller

VALVE MAINTENANCE

Ordinary and extraordinary maintenance interventions, verification and / or testing on all types of valves (ball valves, butterfly valves, clapet valves or non-return valves, control valves, pneumatic valves, semi-automatic valves, automatic valves)

-

Ordinary maintenance

-

Pressing

-

Packing replacement

-

Body gasket replacement

-

Supply of flange gaskets

-

Bulk braid supply

-

Acid wash

-

Sandblasting

-

Floor grinding

-

Valve seat turning

-

Back turning (mushroom)

-

Threaded rod turning

-

Case back construction

-

Threaded rod construction

PUMPS MAINTENANCE

Our staff is able to intervene at every level on existing pumps, renewing their full functionality

-

Checks and checks on any type of pump: manual pumps, electric pumps or motorized pumps

-

Ordinary and extraordinary maintenance on any type of pump: manual pumps, electric pumps or motorized pumps

HATCH ASSEMBLY

Handling and automation of doors, compass doors, hatches and hatches. Realization, control, verification and maintenance of all types of manual and servo-assisted handling systems of:

-

Doors

-

Compass / pantograph doors

-

Curved doors

-

Structural doors

-

Doors in stainless steel

-

Windows / portholes

-

Hatches

-

Hatches

We also offer our experience for custom modifications tailored to each type of hinge, handling and fixing system.

WINDLASS

Maintenance and optimization of the mechanisms, also servo-assisted, of any type of anchor windlass or warp, checking the alignment of the chain axes as well as performing the set-up of the chain adjusters and chain brakes.

-

Engine maintenance

-

Check and align the chain axes

-

Gear check and maintenance

-

Guide set-up and register

-

Chain brake set-up and register

Creation of customized components to modify and / or rebuild systems to resolve any construction defects that affect the perfect functioning of windlasses and warps